Brazil, the wind energy leader in Latin America, continues to offer major opportunities for wind energy development

As part of the country’s 2010 Alternative Energy Auctions, GE (NYSE: GE) today announced commitments from four developers to supply more than 400 megawatts of clean, wind-generated electricity to Brazil’s renewable energy capacity. These commitments include 258 of GE’s advanced 1.5 and 1.6-megawatt wind turbines. GE’s 1.5-megawatt series wind turbines are the most widely deployed wind turbines in the world.

As part of the country’s 2010 Alternative Energy Auctions, GE (NYSE: GE) today announced commitments from four developers to supply more than 400 megawatts of clean, wind-generated electricity to Brazil’s renewable energy capacity. These commitments include 258 of GE’s advanced 1.5 and 1.6-megawatt wind turbines. GE’s 1.5-megawatt series wind turbines are the most widely deployed wind turbines in the world.

Customers making commitments to GE from Brazil’s 2010 Alternative Energy Auction are Renova Energia S.A ., Dobreve Energia S.A. (DESA), Contour Global and Bioenergy. Projects from the four customers are located in the states of Bahia and Rio Grande do Norte.

“Being able to supply the best technology fit for Brazil’s wind conditions is at the center of our continued success in the country’s wind auctions,” said Victor Abate, vice president-renewable energy for GE Power & Water. “We are focused on making our customers the most competitive in Brazil as they concentrate on helping the country reach its renewable energy goals.”

The 2010 auction commitments build upon GE’s success in winning more than 400 megawatts of wind turbine commitments in Brazil’s first technology-specific energy auction, held in 2009.

“We have had success in winning a quarter of the megawatts awarded in the past 12 months in Brazil. These relationships support our positioning as one of Brazil’s wind energy leaders and, most importantly, represent an important step towards our long term vision as key players in this country,” said Jean Claude Robert, GE’s wind director for Latin America.

Details on GE’s commitments resulting from Brazil’s 2010 Alternative Energy Auctions include:

Renova – 163 megawatts with 102 units

DESA – 60 megawatts with 38 units

Contour Global – 150 megawatts with 100 units

Bioenergy – 28.8 megawatts with 18 units

Renova and DESA previously selected GE technology in the 2009 Brazil wind auctions, while Contour Global and Bioenergy are first-time GE customers. GE’s scope with each of the developers will include the supply, erection and commissioning of the wind turbines, along with service agreements of at least two years. GE’s wind turbine technology is part of ecomagination, the company’s commitment to imagine and build innovative solutions to environmental challenges.

Traditionally, Brazil has relied heavily on hydropower for its electricity supply. The recent wind auctions reinforce the country’s commitment to make wind power a mainstream source of energy as it continues to expand its renewable energy portfolio.

Brazil is Latin America’s leading wind market with 31.6 gigawatts of capacity expected to be installed by 2025, according to a recent study from IHS Emerging Energy Research. The study also highlights Brazil’s market scale and proactive renewable energy policies as key elements in creating a steady growth in wind power development for the country.

GE has had a presence in Brazil since 1919 and today employs more than 6,000 people in the country. GE recently announced plans to invest $500 million to expand its operations in Brazil, including $200 million for new wind turbine and aeroderivative product developments and increased capacity for GE’s Oil & Gas business. As part of the expansion, GE is establishing its newest multi-disciplinary research and development center in Rio de Janeiro. Work at the center will focus on advanced technologies for the renewable energy, oil and gas, mining, rail and aviation industries.

Organization provides training to empower erectors leading a new generation of energy-industry construction.

AUSTIN, Texas PRNewswire: As more and more wind turbines are erected across the open plains, farmlands, and mountain ridges of the United States, the need for ironworkers with specialized construction skills has naturally grown, says the Iron Workers International Union. Ask anyone knowledgeable about wind energy, and you’ll quickly learn that the latest “green” technology – despite a recent surge in public interest – is nothing new to union ironworkers. In fact, ironworkers have been erecting wind turbines for decades. What is new is a need for independent certifications-driven largely by increased scrutiny of the wind energy sector – meant to improve safety and quality across the industry. In response, the Iron Workers International Union (www.ironworkers.org) – working with the Ironworker Management Progressive Action Cooperative Trust (IMPACT) – is offering wind turbine training programs for union ironworkers to develop key construction skills. Through a new IMPACT (www.impact-net.org) program, certification in torque/tension and tower-climbing and safety procedures, including high-angle rescue procedures, comes from industry-recognized leaders, including Capital Safety (DBI/SALA) (www.capitalsafety.com), Snap-on Industrial (www.snapon.com), and HYTORC.

AUSTIN, Texas PRNewswire: As more and more wind turbines are erected across the open plains, farmlands, and mountain ridges of the United States, the need for ironworkers with specialized construction skills has naturally grown, says the Iron Workers International Union. Ask anyone knowledgeable about wind energy, and you’ll quickly learn that the latest “green” technology – despite a recent surge in public interest – is nothing new to union ironworkers. In fact, ironworkers have been erecting wind turbines for decades. What is new is a need for independent certifications-driven largely by increased scrutiny of the wind energy sector – meant to improve safety and quality across the industry. In response, the Iron Workers International Union (www.ironworkers.org) – working with the Ironworker Management Progressive Action Cooperative Trust (IMPACT) – is offering wind turbine training programs for union ironworkers to develop key construction skills. Through a new IMPACT (www.impact-net.org) program, certification in torque/tension and tower-climbing and safety procedures, including high-angle rescue procedures, comes from industry-recognized leaders, including Capital Safety (DBI/SALA) (www.capitalsafety.com), Snap-on Industrial (www.snapon.com), and HYTORC.

To provide just-in-time training for ironworker local unions and signatory contractors, the Iron Workers Union (IWU) has teamed with the Francis Tuttle Technology Center (FTTC) in Oklahoma City, Oklahoma. The FTTC (www.francistuttle.edu) is a member of the Wind Energy Training Consortium, a group of training institutions-brought together by Snap-on Industrial in February, 2009-that’s now recognized by the American Wind Energy Association (www.awea.org) as promoting essential skills training for wind turbine technicians.

The 36-hour course, spanning four days, focuses on two major areas of wind turbine construction: tower safety and torque/tension certification. Each session trains up to 10 ironworkers.

In tower safety and rescue training, ironworkers learn about fall protection, as well as high-angle rescue and evacuation techniques, and types of equipment. Specifically, ironworkers learn the proper use, care, and maintenance of height-safety equipment. With successful completion, ironworkers receive a nationally recognized DBI Tower Safety Certificate. In torque/tension training, ironworkers can gain certification in the use of basic fasteners and proper safety procedures, along with mechanical, electronic and hydraulic torque knowledge. Hands-on learning is enabled by torque-tooling industry leaders Snap-on Industrial and HYTORC. Successful completion of this course component provides three industry recognized certifications. The training continues to reinforce the Iron Worker’s “iron-clad commitment to the highest jobsite-safety standards [that help] protect ironworkers’ health, and make jobs more profitable,” says Marvin Ragsdale, president of the Iron Workers District Council of Texas and the Mid-South States (www.ironworkerstxmidsouth.com).

Harvey Swift, assistant director of education and training for IMPACT, says union ironworkers present a real advantage to the investors behind wind farm projects. “With continuous, advanced training, today’s union ironworkers are more highly skilled than ever before,” says Swift. “Now, this includes skills that they can immediately apply on ‘green’ construction jobs.”

Part of the American Recovery and Reinvestment Act of 2009, a U.S. Department of Labor Energy Training Partnership Grant has enabled IMPACT to replicate the FTTC training model in five U.S. cities: Buffalo, NY; Dallas, Joliet, IL; Los Angeles; and Salt Lake City. Each location can train up to 100 ironworkers within the program’s plan. Julio Gonzalez is the apprenticeship and training coordinator for Iron Workers Union Local 263 in Dallas/Fort Worth. Gonzalez points out that “While ironworkers and their contractors have led the way building and maintaining turbines, the new training program adds requisite turbine-industry certification to ironworkers’ broad construction skill sets.” “For years, our union ironworkers have been trained to safely erect and maintain wind turbines. Now they have industry-standard certification to validate their skills,” says Greg Schulze, apprenticeship and training coordinator for the IWU in Texas.

Due to the advanced coursework, only journeymen ironworkers with a minimum of three years of field experience who have completed OSHA 10, Subpart R and First Aid/CPR/AED training are eligible for IMPACT’s Wind Turbine Erection Training. Representing the Iron Workers Union, Schulze and Gonzalez will attend the AWEA Wind Energy Fall Symposium’s Wind Power Health & Safety Workshop, October 26-27, in Austin. For information about the event, visit http://www.awea.org/events/safety10.

The wind cries transmission

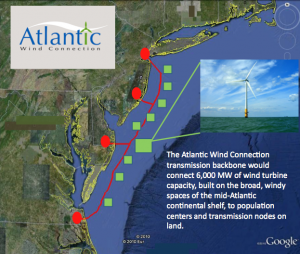

Google: We just signed an agreement to invest in the development of a backbone transmission project off the Mid-Atlantic coast that offers a solid financial return while helping to accelerate offshore wind development—so it’s both good business and good for the environment. The new project can enable the creation of thousands of jobs, improve consumer access to clean energy sources and increase the reliability of the Mid-Atlantic region’s existing power grid.

Google: We just signed an agreement to invest in the development of a backbone transmission project off the Mid-Atlantic coast that offers a solid financial return while helping to accelerate offshore wind development—so it’s both good business and good for the environment. The new project can enable the creation of thousands of jobs, improve consumer access to clean energy sources and increase the reliability of the Mid-Atlantic region’s existing power grid.

When built out, the Atlantic Wind Connection (AWC) backbone will stretch 350 miles off the coast from New Jersey to Virginia and will be able to connect 6,000MW of offshore wind turbines. That’s equivalent to 60% of the wind energy that was installed in the entire country last year and enough to serve approximately 1.9 million households.

The AWC backbone will be built around offshore power hubs that will collect the power from multiple offshore wind farms and deliver it efficiently via sub-sea cables to the strongest, highest capacity parts of the land-based transmission system. This system will act as a superhighway for clean energy. By putting strong, secure transmission in place, the project removes a major barrier to scaling up offshore wind, an industry that despite its potential, only had its first federal lease signed last week and still has no operating projects in the U.S.

Why offshore wind and why the Mid-Atlantic? Many coastal areas in the United States have large population centers on an overstretched grid but limited access to a high-quality land-based wind resource. These coastal states can take advantage of their most promising renewable resource by using larger wind farms with larger turbines that can take advantage of stronger and steadier winds offshore.

The Mid-Atlantic region is ideally suited for offshore wind. It offers more than 60,000 MW of offshore wind potential in relatively shallow waters that extend miles out to sea. These shallow waters make it easier to install turbines 10-15 miles offshore, meaning wind projects can take advantage of stronger winds and are virtually out-of-sight from land. With few other renewable energy options ideally suited for the Atlantic coast, the AWC backbone helps states meet their renewable energy goals and standards (PDF) by enabling a local offshore wind industry to deploy thousands of megawatts of clean, cost-effective wind energy.

The AWC backbone is critical to more rapidly scaling up offshore wind because without it, offshore wind developers would be forced to build individual radial transmission lines from each offshore wind project to the shore, requiring additional time consuming permitting and environmental studies and making balancing the grid more difficult. As those in the Northeast remember from the 2003 blackout, transmission is severely overstretched on the east coast. The AWC project relieves grid congestion in one of two National Interest Electric Transmission Corridors which were deemed to have significant network congestion and need speedy creation of transmission capacity.

The AWC project is led by independent transmission company Trans-Elect and is financed by Google, Good Energies and Marubeni Corporation. We are investing 37.5% of the equity in this initial development stage, with the goal of obtaining all the necessary approvals to finance and begin constructing the line. Although the development stage requires only a small part of the total estimated project budget, it represents a critical stage for the project.

We believe in investing in projects that make good business sense and further the development of renewable energy. We’re willing to take calculated risks on early stage ideas and projects that can have dramatic impacts while offering attractive returns. This willingness to be ahead of the industry and invest in large scale innovative projects is core to our success as a company.

From the Great Plains to the waters off the coast of Northern Europe, windmills churn out clean power that lights our homes and powers our economies. We are pleased to support this investment that will ultimately enable the Mid Atlantic to benefit from the tremendous wind resource off its coast. Posted by Rick Needham, Green Business Operations Director

The Anaconda produces wave energy

Wave energy is a particularly rich, but as yet untapped, energy resource which government studies state could produce 3%-5% of our electricity initially and up to 20% eventually.

The Anaconda project team has been testing a scaled device, part of a programme of rigorous development, completing the final stage of an exhaustive proof of concept phase at QinetiQ’s Haslar Marine Technology Park at Gosport, Hampshire using the UK’s largest wave testing facility where the strength and frequency of ocean waves the device may encounter can be simulated.

Paul Auston, Chairman of the Checkmate Group, said: “The UK is known for its engineering excellence and politicians of all parties have been keen to challenge companies to come up with renewable energy projects that can be sold around the world. With Anaconda we have an invention that changes conventional thinking and it will help to meet the ambitious government target of providing renewable wave energy from our coastal waters. It will also help cement the UK’s world leading position in this technology.”

“We’ve seen excellent results in scale model testing, and we are now gearing up to attract the necessary investment to develop Anaconda and take this proven concept through to full commercialisation within the next five years.”

Water Surge

Hydropower, once shunned because of environmental concerns, is making a comeback

By STEPHANIE SIMON – LEADVILLE, Colo.—The giant pipes wheeze and rumble, the whoosh of water coursing through them as noisy as a freeway. The Mount Elbert hydropower plant high in the Rocky Mountains isn’t much to look at—or listen to. But to true believers, it’s a road map to a greener future.

By STEPHANIE SIMON – LEADVILLE, Colo.—The giant pipes wheeze and rumble, the whoosh of water coursing through them as noisy as a freeway. The Mount Elbert hydropower plant high in the Rocky Mountains isn’t much to look at—or listen to. But to true believers, it’s a road map to a greener future.

Larissa Bender, Bureau of Reclamation

The Mount Elbert plant (center) in Colorado uses pumped storage to generate electricity. Using wind power or cheap electricity from the grid overnight, it pumps water from the lake in the foreground through underground pipes to the reservoir above the plant. At times of high demand, it runs the water back down through the plant and its turbines to make electricity. Hydropower, shunned just a few years ago as an environmental scourge, is experiencing a remarkable resurgence in the U.S. Dams are still viewed warily; in fact, Congress is considering dismantling four hydroelectric dams blamed for depleting salmon in the Klamath River basin in southern Oregon and northern California.

But engineers and entrepreneurs are pressing an alternative view of hydropower that doesn’t involve new dams. They argue that plenty of efficient, economical energy can be wrung from other water resources, including ocean waves, free-flowing rivers, irrigation ditches—even the effluent discharged from wastewater treatment facilities. There’s a surge of interest, too, in adding small power plants to dams built years ago for flood control or navigation—as well as in turning reservoirs into battery packs of sorts, releasing energy when the grid needs it most.

Journal Reports

Read the complete Energy report .

Globally, hydropower provides 16% of electricity, slightly more than nuclear power and closing in on natural gas, according to the London-based International Hydropower Association.

In the U.S., by contrast, hydropower now provides about 7% of electricity generation. All other renewable sources combined account for about 3%.

Even without building large dams, expanding efforts to draw power from water could add 40,000 megawatts to the grid by 2025, says the Electric Power Research Institute, a nonprofit research firm in Palo Alto, Calif. That’s the equivalent of putting at least two dozen new nuclear power plants online.

Pouring It On

Such estimates are stirring action. The U.S. Department of Energy spent nothing on hydropower research as recently as 2007 but allocated $50 million this year. The Federal Energy Regulatory Commission issued 50 preliminary permits for small hydro projects last year, up from 15 in 2007. At least two dozen states have mandated that utilities draw more power from renewable sources—and many include small hydropower as an option, along with wind and solar. Colorado Gov. Bill Ritter recently announced an agreement between his state and the federal government that will streamline the permitting process for developing small hydropower projects in Colorado. Read the full article: Water Surge